Electroslag Welding - Advantages and Disadvantages

Electroslag Welding Advantages and Disadvantages:

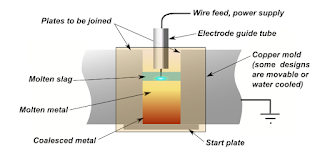

What Is Electroslag Welding?

Image Source: Click Here

Advantages of Electroslag welding

- Due to the slow cooling rate, cold cracking does not occur.

- High productivity can be achieved.

- It is a Low-cost process.

- In this process, slag inclusion or porosity does not affect.

- This welding process is faster.

- This is a semi-automatic process.

- The slag remaining is eliminated.

- A heavier section can be welded in a single pass.

- This process can weld Heavy parts easily.

- Low distortion.

Disadvantages of Electroslag welding:

- It required additional cooling for high-temperature welds.

- The quality of the welding decreases in the fusion zone and the heat-affected zone if the supply of heat is high.

- Cracking may occur in the heat-affected zone.

- It is only useful for vertical position welding.

- It has low toughness to the weld.

- Due to the high heat base meat gets hotter.

This is actually the kind of information I have been trying to find. Thank you for writing this information. Nft projects

ReplyDeleteUpdates are delivered in our Discord server dedicated for customers and we offer support for everyone in case tutorials are not enough. We also try to provide updates in a timely manner. pubg logitech

ReplyDeleteI'm so glad we chose Burlington Lakeshore Vet as our vet! Everyone is so kind and helpful. Dr. Aziz always take the best care of my dog and I feel very ... burlington vet hospital

ReplyDelete